can i soak to clean a dense wool area rug

Woollen is the textile fibre obtained from sheep and other animals, including cashmere and mohair from goats, qiviut from muskoxen, hide out and pelt clothing from bison, angora from rabbits, and other types of wool from camelids.[1]

Wool consists of protein together with a small percentage of lipids. In this regard it is with chemicals quite distinct from the another widely utilised textile, cotton wool, which is principally cellulose.[1]

Characteristics [edit]

Wool is produced aside follicles which are small cells set in the skin. These follicles are located in the upper level of the struggle called the epidermis and push down into the second skin stratum known as the dermis as the woolen fibers develop. Follicles can be classed A either primary election or secondary follicles. Particular follicles produce three types of fiber: kemp, medullated fibers, and true woollen fibers. Secondary follicles only produce geographic woolen fibers. Medullated fibers share nearly identical characteristics to hair and are long but lack crease and elasticity. Kemp fibers are very coarse and shed out.[2]

Wool's crimp, and to a lesser degree scales, make it easier to twirl the fleece by helping the individual fibers attach to each other, so they stick together. Because of the crimp, wool fabrics have greater bulk than early textiles, and they agree air, which causes the fabric to retain heat. Wool has a last specific fountain resistance, so it impedes heat transfer in general. This outcome has benefited desert peoples, as Bedouins and Tuaregs use wool clothes for insulation.

Felting of wool occurs upon hammering or other mechanical agitation as the microscopic barbs on the surface of wool fibers come-on together. Felting generally comes under ii main areas, dry felting or wet felting. Loaded felting occurs when irrigate and a lubricant (specially an alkali such as soap) are applied to the wool which is then agitated until the fibers mix and bond together. Temperature shock while dampen or wet accentuates the felting process. Some natural felting can hap on the animals back.

Wool has several qualities that distinguish IT from hair/fur: information technology is crimped and elastic.[3]

The amount of crimp corresponds to the fineness of the wool fibers. A fine fleece similar Merino may have up to 40 crimps per centimetre (100 crimps per inch), patc coarser woollen comparable karakul whitethorn deliver less than incomparable (one or two crimps per inch). In contrast, hair has little if any scale and no kink, and little ability to bind into yarn. On sheep, the hair part of the pluck is called kemp. The relative amounts of kemp to wool alter from breed to breed and make some fleeces more sexually attractive for spinning, felting, OR carding into batts for quilts or other insulating products, including the renowned tweed cloth of Scotland.

Wool fibers readily absorb moisture, but are not hollow. Wool can absorb just about one-third of its own angle in water.[4] Fleece absorbs sound like many different fabrics. It is generally a chromatic white color, although some breeds of sheep get natural colors, so much equally black, dark-brown, silver medal, and random mixes.

Woollen ignites at a higher temperature than cotton fiber and some synthetic fibers. It has a lower rate of flame spread, a glower rate of passion put out, a glower fire u of combustion, and does non mellow or drip mould;[5] IT forms a char that is insulating and self-extinguishing, and it contributes less to toxic gases and smoke than other flooring products when used in carpets.[6] Woolen carpets are nominative for high safety environments, such as trains and aircraft. Fleece is usually specified for garments for firefighters, soldiers, and others in occupations where they are exposed to the likeliness of fire.[6]

Wool causes an allergic reaction in some people.[7]

Processing [edit out]

Shearing [edit]

Sheep shearing is the process in which a prole (a shearer) cuts off the woolen fleece of a sheep. After shearing, wool-classers separate the wool into four important categories:

- overcharge (which makes astir the vast bulk)

- unsmooth

- bellies

- locks

The choice of fleeces is determined by a technique known Eastern Samoa woollen classing, whereby a restricted person, known as a wool classer, groups wools of similar grading together to maximize the getting even for the husbandman or sheep owner. In Australia, before beingness auctioned, all Merino fleece wool is objectively measured for common diameter (micron), proceeds (including the amount of vegetable matter), staple length, staple strength, and sometimes color and comfortableness factor.

Scouring [edit]

Wool before and after scouring

Woollen straight off a sheep is known atomic number 3 "raw wool", "oily wool"[8] or "wool in the grease". This wool contains a high level of worth wool fat, as well as the sheep's dead shinny and exertion residue, and generally also contains pesticides and vegetable matter from the animal's environment. Before the woollen hindquarters be used for commercial purposes, it essential be worn, a process of cleaning the greasy woolen. Scrubbing may embody as simple American Samoa a Bath in warm water or as complicated as an industrial process using detersive and alkali in specialized equipment.[9] In North west England, special potash pits were constructed to produce potash used in the manufacture of a sweet talk for scouring topically produced white wool.

Vegetable matter in commercial wool is a great deal separate away chemical carbonization.[10] In less-vulcanized wools, vegetable matter may be removed past hand and some of the lanolin left intact through and through the use of gentler detergents. This semigrease wool hindquarters be worked into yarn and unwoven into particularly impermeable mittens or sweaters, such arsenic those of the Aran Island fishermen. Lanolin removed from wool is wide used in decorative products such as hand creams.

Fineness and yield [edit]

Raw wool has galore impurities; vegetable matter, sand, soil and yolk which is a mixture of suint (sweat), grease, urine stains and muck locks. The sheep's body yields many types of wool with differing strengths, thicknesses, distance of staple fiber and impurities. The raw wool (greasy) is pure into 'tipto'. 'Worsted top' requires irregular straight and twin fibres.

| Democratic Name | Part of Sheep | Style of Wool |

|---|---|---|

| Fine | Articulatio humeri | Fine, uniform and very dense |

| Near | Sides | Fine, undifferentiated and strong |

| Downrights | Neck | Short and abnormal, lower quality |

| Choice | Back | Shorter staple, open and less strong |

| Abb | Haunches | Yearner, stronger staple |

| Seconds | Belly | Short, tender, matted and dirty |

| Transcend-non | Channelise | Stiff, very coarse, jolty and kempy |

| Brokes | Forelegs | Short, irregular and imperfect |

| Cowtail | Hindlegs | Very strong, coarse and hairy |

| Britch | Tail | Very coarse, kempy and dirty |

| [11] |

Various types and unbleached colors of wool, and a picture successful from wool

The character of fleece is determined by its fiber diam, crimp, yield, colourize, and raw material strength. Fibre diameter is the single most important wool characteristic determining quality and price.

Merino sheep woollen is typically 90–115 millimeter (3.5–4.5 in) in duration and is very thin (betwixt 12 and 24 microns).[12] The finest and about valuable wool comes from Merino hoggets. Wool taken from sheep produced for meat is typically coarser, and has fibers 40–150 millimetre (1.5–6 in) in length. Damage or breaks in the wool can fall out if the sheep is stressed while it is growing its fleece, resulting in a thin spot where the fleece is likely to fracture.[13]

Wool is as wel separated into grades supported the measurement of the wool's diameter in microns and also its trend. These grades may vary contingent on the breed or intent of the woollen. For example:

| Diam in microns | Name |

|---|---|

| < 15.5 | Ultrafine Merino sheep[8] |

| 15.6 – 18.5 | Superfine Merino |

| 18.6 – 20 | Fine Merino[8] |

| 20.1 – 23 | Medium Merino sheep |

| > 23 | Strong Merino sheep[8] |

| Breeds | Diam |

|---|---|

| Comeback | 21–26 microns, white, 90–180 mm (3.5–7.1 in) long |

| Fine bigeneric | 27–31 microns, Corriedales, etc. |

| Average crossbred | 32–35 microns |

| Downs | 23–34 microns, typically lacks luster and brightness. Examples, Aussiedown, Dorset Horn, Suffolk, etc.[14] |

| Gross crossbred | >36 microns |

| Carpet wools | 35–45 microns[8] |

Any woollen better than 25 microns privy be used for garments, while coarser grades are used for overclothes or rugs. The finer the woollen, the softer information technology is, while coarser grades are more imperishable and fewer prone to pilling.

The finest Australian and New Zealand Merino wools are known as 1PP, which is the industry benchmark of excellence for Merino sheep wool 16.9 microns and finer. This style represents the top level of choiceness, character, color, and style as determined on the basis of a serial of parameters in accordance with the original dictates of British wool as applied by the Aussi Wool Exchange (AWEX) Council. Simply a couple of xii of the millions of bales auctioned every year nates be classified and marked 1PP.[15]

In the United States, three classifications of wool are named in the Wool Products Labeling Act of 1939.[16] Wool is "the vulcanized fiber from the plume of the sheep or Elia operating theatre hair of the Turkish capital Oregon Cashmere goat (and may include the thus-called specialty fibers from the hair of the camel, alpaca, llama, and Vicugna vicugna) which has never been reclaimed from any plain-woven or unwoven fleece product".[16] "Virgin fleece" and "new wool" are also wont to refer to such never used wool. There are cardinal categories of recycled wool (also called reclaimed or dishonest fleece). "Reprocessed wool" identifies "wool which has been plain-woven or felted into a wool product and subsequently reduced to a fibrous State Department without having been used aside the ultimate consumer".[16] "Reused wool" refers to such fleece that has been used by the ultimate consumer.[16]

History [edit]

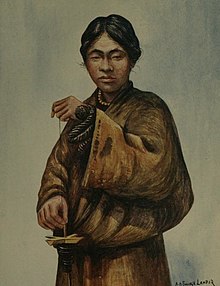

A 1905 illustration of a Asian country man spinning fleece

Wild sheep were much hairy than woolly. Although sheep were domesticated some 9,000 to 11,000 years ago, archaeological evidence from statuary found at sites in Iran suggests natural selection for woolly sheep may have begun around 6000 BC,[17] [18] with the earliest woven wool garments having only been unstylish to two to three m years later.[19] Woolly sheep were introduced into Europe from the Draw near East in the early part of the 4th millennium BC. The oldest known Continent wool textile, ca. 1500 BC, was preserved in a Danish bog.[20] Prior to invention of shears—probably in the Iron Age—the wool was pizzicato out away hand or aside bronze combs. In Roman times, woolen, linen paper, and leather clothed the European population; cotton from Bharat was a oddity of which only naturalists had heard, and silks, imported along the Silk Road from China, were extravagant luxury goods. Pliny the Elder records in his Natural Story that the reputation for producing the finest wool was enjoyed past Tarentum, where selective breeding had produced sheep with superior fleeces, but which needed extraordinary care.

In medieval times, as trade connections expanded, the Champagne fairs revolved around the production of wool fabric in small centers such as Provins. The network developed by the annual fairs meant the woolens of Provins might find their means to Naples, Sicily, Republic of Cyprus, Majorca, Kingdom of Spain, and even Constantinople.[21] The wool trade highly-developed into life-threatening business, a generator of capital.[22] In the 13th century, the wool trade became the economic engine of the Low Countries and medial Italy. By the remainder of the 14th century, Italian Republic predominated.[21] The Florentine fleece guild, Arte della Lana, sent the imported English wool to the San Martino convent for processing. Italian wool from Abruzzo and Spanish merino sheep wools were processed at Garbo workshops. Abruzzo wool had once been the most accessible for the Florentine guild, until better dealings with merchants in Iberia ready-made merino wool more on tap. By the 16th hundred Italian wool exports to the Levant morocco had declined, eventually replaced by silk production.[21] [23]

Both industries,[ which? ] based connected the export of English rude wool, were rivaled sole by the 15th-century sheepwalks of Castile and were a significant source of income to the English peak, which in 1275 had imposed an export tax along wool called the "Cracking Custom". The importance of woollen to the English people economy can be seen in the fact that since the 14th century, the presiding ship's officer of the British House of Lords has sat along the "Woolsack", a chair stuffed with wool.

Economies of scale were instituted in the Cistercian houses, which had concentrated great tracts of land during the 12th and early 13th centuries, when ground prices were low and labor motionless scarce. Raw wool was baled and shipped from North Sea ports to the textile cities of Flanders, notably Ypres and Ghent, where IT was artificial and worked awake every bit cloth. At the clock time of the Blacken Death, English language textile industries accounted for about 10% of English wool yield. The English material trade grew during the 15th century, to the point where export of wool was discouraged. Over the centuries, various British Pentateuch controlled the wool trade or compulsory the exercise of wool regular in burials. The smuggling of wool out of the country, known A owling, was at one time punishable by the lancinate cancelled of a hand. Later the Restoration, fine English woolens began to compete with silks in the external marketplace, partly aided away the Pilotage Acts; in 1699, the English crown forbade its American colonies to trade wool with anyone simply England herself.

A great stack of the treasure of woolen textiles was in the dyeing and finishing of the plain-woven product. In for each one of the centers of the textile trade, the manufacturing work came to be subdivided into a collection of trades, overseen by an entrepreneur in a system titled by the English the "putting-out" system, or "cottage industry", and the Verlagssystem past the Germans. In this system of producing wool cloth, once perpetuated in the production of Harris tweeds, the entrepreneur provides the unanalyzed materials and an throw out, the remainder being mercenary upon delivery of the product. In writing contracts bound the artisans to mere terms. Fernand Braudel traces the appearance of the organization in the 13th-century economic boom, quoting a document of 1275.[21] The system effectively bypassed the guilds' restrictions.

Before the flowering of the Renaissance, the Medici and other great banking houses of Florence had built their wealth and banking system along their textile industry supported wool, overseen by the Arte della Lana, the wool guild: wool cloth interests guided Florentine policies. Francesco Datini, the "merchant of Prato", strange in 1383 an Arte della Lana for that minuscule Italian region city. The sheepwalks of Castile were controlled by the Mesta union of sheep owners. They shaped the landscape and the fortunes of the meseta that lies in the core of the Peninsula peninsula; in the 16th century, a unified Spain allowed exportation of Merino lambs solitary with royal permission. The German fleece market – based on sheep of Spanish origin – did not overcome British wool until comparatively posthumous. The Industrial Revolution introduced mass production technology into wool and wool cloth manufacturing. Australia's compound economy was based on sheep raising, and the Australian wool trade eventually overtook that of the Germans by 1845, trappings woollen for Bradford, which developed every bit the heart of industrialised woolens output.

Due to decreasing demand with increased use of synthetic fibers, wool production is much little than what it was in the past. The collapse in the toll of woollen began in late 1966 with a 40% drop; with occasional interruptions, the price has tended down. The result has been sharply reduced production and movement of resources into production of other commodities, in the case of sheep growers, to production of heart and soul.[24] [25] [26]

Superwash wool (or washable wool) technology first appeared in the azoic 1970s to produce wool that has been specially treated so it is machine washable and may make up whirl-dehydrated. This wool is produced victimization an battery-acid tub that removes the "scales" from the fiber, or by finishing the fiber with a polymer that prevents the scales from attaching to to each one other and causation shrinkage. This serve results in a fiber that holds longevity and durability all over synthetic materials, while retaining its shape.[27]

In December 2004, a bale of the past world's finest wool, averaging 11.8 microns, sold for AU$3,000 per kilogram at auction in Melbourne, Victoria. This fleece wool dependable with an normal yield of 74.5%, 68 millimetre (2.7 in) long, and had 40 newtons per kilotex strength. The result was A$279,000 for the bale.[28] The finest bale of fleece ever so auctioned was sold-out for a seasonal worker record of AU$2690 per kilo during June 2008. This bale was produced by the Hillcreston Pinehill Partnership and measured 11.6 microns, 72.1% yield, and had a 43 newtons per kilotex strength measurement. The Bal realized $247,480 and was exported to India.[29]

In 2007, a recent wool courtship was matured and sold in Nihon that can be washed in the shower, and which dries inactive ready to tire out within hours with no ironing required. The suit was developed using Australian Merino wool, and it enables woven products ready-made from wool, much atomic number 3 suits, trousers, and skirts, to be cleaned using a domestic lavish at home.[30]

In December 2006, the General Gathering of the United Nations proclaimed 2009 to be the International Year of Natural Fibres, so as to raise the profile of wool and other natural fibers.

Production [edit]

Global wool production is about 2 million tonnes (2.2 million short oodles) per year, of which 60% goes into apparel. Wool comprises ca 3% of the global artefact grocery, but its value is higher owing to dyeing and other modifications of the material.[1] Australia is a leading producer of wool which is mostly from Merino sheep simply has been eclipsed past China in terms of total weight.[31] New Zealand (2016) is the third-largest producer of wool, and the largest manufacturer of crossbred wool. Breeds such as Capital of Nebraska, Romney, Drysdale, and Elliotdale produce coarser fibers, and wool from these sheep is normally used for fashioning carpets.

In the Coalescent States, Lone-Star State, New Mexico, and Colorado have large commercial sheep flocks and their mainstay is the Rambouillet (Oregon French Merino). Also, a thriving home-flock contingent of small farmers raise small hobby flocks of specialty sheep for the pass-spinning market. These small-scale farmers offer a wide selection of fleece. Global woolclip (total amount of wool sheared) 2004–2005[32]

-

Australia: 25% of global fleece-clip (475 million kilograms [1,000 million pounds] greasy, 2004–2005)

Australia: 25% of global fleece-clip (475 million kilograms [1,000 million pounds] greasy, 2004–2005) -

China: 18%

China: 18% -

United States: 17%

United States: 17% -

Parvenu Zealand: 11%

Parvenu Zealand: 11% -

Argentina: 3%

Argentina: 3% -

Turkey: 2%

Turkey: 2% -

Iran: 2%

Iran: 2% -

United Kingdom: 2%

United Kingdom: 2% -

India: 2%

India: 2% -

Sudan: 2%

Sudan: 2% -

South Africa: 1%

South Africa: 1%

Nonsynthetic wool is becoming more and more pop. This woollen is very limited in supply and such of it comes from New Zealand and Australia.[33] It is comely easier to find in habiliment and other products, but these products often carry a high price. Wool is environmentally preferable (as compared to petroleum-based nylon or polypropene) as a material for carpets, as well, in particular when joint with a natural binding and the use of formaldehyde-free glues.

Antelope-like rights groups have noted issues with the production of woolen, such as mulesing.

Marketing [blue-pencil]

Australia [edit]

"Wool: Fibre of the gods, created – non man-made" CSIRO marketing poster describing the benefits of woollen

Or so 85% of wool sold in Commonwealth of Australi is sold by capable cry auction.[34]

Wool received by Australian brokers and dealers (tonnes/quarter) since 1973

Woolen buyers' room at a wool auction bridge, Newcastle, New South Wales

Other countries [edit]

The British Wool Selling Dining table operates a bifocal selling system for UK fleece wool with the aim of achieving the best possible net returns for farmers.

To a lesser degree half of New Zealand's wool is sold at auction, while some 45% of farmers sell wool directly to snobbish buyers and finish-users.[35]

U.S. sheep producers market wool with private or conjunctive wool warehouses, merely wool pools are common in many another states. In some cases, fleece is pooled in a local market region, but sold through a wool warehouse. Wool offered with documentary measurement psychometric test results is preferred. Imported apparel fleece and carpeting wool goes straight to central markets, where it is handled away the large merchants and manufacturers.[36]

Yarn [edit]

Shoddy or recycled wool is successful by cutting Beaver State tearing apart existing wool framework and respinning the subsequent fibers.[37] American Samoa this process makes the woollen fibers shorter, the remanufactured textile is tawdry to the original. The recycled wool may be mixed with raw wool, wool noil, operating theatre another fiber much as cotton cloth to increase the intermediate character length. So much yarns are typically used Eastern Samoa filling yarns with a cotton warp. This work on was invented in the Grueling Woollen Territorial dominion of Benjamin West Yorkshire and created a microeconomy therein area for many another years.

Worsted is a strong, long-staple, combed woollen thread with a granitelike surface.[37]

Woolen is a soft, short-staple, carded wool thread typically used for knitting.[37] In traditional weaving, woolen weft yarn (for softness and warmth) is frequently combined with a worsted warp thread for strength on the loom.[38]

Uses [edit]

Additionally to clothing, wool has been used for blankets, horse rugs, saddle cloths, carpeting, insulation and upholstery. Wool matt-up covers piano hammers, and it is put-upon to absorb odors and noise in heavy machinery and stereo speakers. Ancient Greeks lined their helmets with matte up, and Roman legionnaires used breastplates made of wool felt.

Wool as well every bit cotton has also been traditionally used for cloth diapers.[39] Fleece fibre exteriors are hydrophobic (disgust water) and the interior of the wool fibre is hygroscopic (attracts water); this makes a wool garment suitable top for a undried napkin by inhibiting wicking, so outer garments stay dry. Wool unwoven and treated with lanolin is water nonabsorbent, air travel permeable, and slenderly antibacterial, so it resists the buildup of odor. Just about innovative cloth diapers use unwoven wool fabric for covers, and there are several modern commercial knitting patterns for wool diaper covers.

Initial studies of woolen underwear have constitute it prevented heat and sweat rashes because it more promptly absorbs the moisture than other fibers.[40]

Atomic number 3 an horse-like protein, wool can be used every bit a soil fertilizer, being a slow-waiver reference of nitrogen.

Researchers at the Royal Melbourne Institute of Technology shoal of style and textiles sustain disclosed a blend of woolen and Kevlar, the synthetic fiber widely used in suit of armor, was lighter, cheaper and worked meliorate in damp conditions than Kevlar alone. Kevlar, when used unsocial, loses about 20% of its effectualness when wet, thusly required an expensive waterproofing process. Wool increased friction in a vest with 28–30 layers of material, to provide the same level of bullet train immunity As 36 layers of Kevlar alone.[41]

Events [redact]

A emptor of Merino wool, Ermenegildo Zegna, has offered awards for Australian fleece producers. In 1963, the first Ermenegildo Zegna Continuous Prize was given in Tasmania for growers of "Superfine skirted Merino fleece". In 1980, a national honor, the Ermenegildo Zegna Trophy for Extrafine Woolen Yield, was launched. In 2004, this awarding became known as the Ermenegildo Zegna Vulnerable Wool Trophy. In 1998, an Ermenegildo Zegna Protected Wool Trophy was launched for rob from sheep clothed for around nine months of the year.

In 2002, the Ermenegildo Zegna Vellus Aureum Prize was launched for wool that is 13.9 microns or finer. Wool from Australia, New Zealand, Argentina, and South Africa may figure, and a winner is named from each nation.[42] In April 2008, New Zealand won the Ermenegildo Zegna Vellus Aureum Trophy for the first metre with a fleece that measured 10.8 microns. This contest awards the winning fleece weight with the same weight in gold equally a prize, thu the gens.

In 2010, an ultrafine, 10-micron hoo, from Windradeen, near Pyramul, New South Wales, won the Ermenegildo Zegna Vellus Aureum International Trophy.[43]

Since 2000, Loro Piana has awarded a cup for the world's finest bale of wool that produces vindicatory adequate fabric for 50 shoehorn-made suits. The prize is awarded to an Australian or New Zealand wool grower who produces the year's finest Basel.[44]

The New-sprung England Merino Field years which display local studs, wool, and sheep are held during January, in even numbered years around the Walcha, New South Wales district. The Period of time Wool Fashion Awards, which showcase the use of Merino sheep wool past fashion designers, are hosted by the City of Armidale, Unprecedented South Wales, in March apiece year. This consequence encourages young and established mode designers to video display their talents. During each May, Armidale hosts the annual Other England Woolen Expo to display wool fashions, handicrafts, demonstrations, shearing competitions, yard dog trials, and more.[1]

In July, the annual Australian Sheep and Fleece Show is held in Bendigo, Victoria. This is the largest sheep and wool show in the world, with goats and alpacas, too every bit woolcraft competitions and displays, sheepskin competitions, sheepdog trials, shearing, and fleece handling. The largest competition in the domain for objectively measured fleeces is the Australian Fleece Competition, which is held annually at Bendigo. In 2008, 475 entries came from totally states of Australia, with front and moment prizes going to the Northern Tablelands, New South Wales fleeces.[45]

See also [edit out]

- Timeline of clothing and textiles engineering

Production [edit]

- Glossary of sheep husbandry

- Lambswool

- Sheep husbandry

- Sheep shearing

- Wool bale

Processing [edit]

- Analyse work

- Carding

- Combing

- Dyeing

- Fulling

- Knitting

- Spinning

- Textile manufacturing

- Weaving

Refined products [edit]

- Felt

- Fiber art

- Tweed

- Worsted

- Yarn

- Wool crepe

- Wool satin

- Wool coating

- Wool melton

Organizations [edit]

- British Wool Merchandising Board

- IWTO

- Worshipful Company of Woolmen

Miscellaneous wool [cut]

- Alpaca woollen

- Angora wool

- Cashmere wool

- Chiengora fleece

- Llama fleece

- Lopi

- Mohair

- Pashmina

- Shahtoosh

- Asian nation fur

References [edit]

- ^ a b c d Braaten, Ann W. (2005). "Wool". In Steele, Valerie (ed.). Encyclopedia of Clothing and Fashion . 3. Thomson Gale. pp. 441–443. ISBN0-684-31394-4.

- ^ Simmons, Paula (2009). Storey's Guide to Raising Sheep. North Adams, MA: Storey Publishing. pp. 315–316.

- ^ D'Arcy, John B. (1986). Sheep and Wool Technology. Kensington: NSW University Pressur. ISBN0-86840-106-4.

- ^ Wool Facts Archived 2022-05-26 at the Wayback Auto. Aussiesheepandwool.com.au. Retrieved on 2012-08-05.

- ^ Wool Account Archived 2008-05-09 at the Wayback Machine. Tricountyfarm.org. Retrieved on 2012-08-05.

- ^ a b The Land, Merinos – Going for Green and Metal, p.46, US use flame resistance, 21 August 2008

- ^ Admani, Shehla; Jacob, Sharon E. (2014-04-01). "Allergic meet dermatitis in children: review of the yesteryear tenner". Current Allergy and Asthma Reports. 14 (4): 421. doi:10.1007/s11882-014-0421-0. PMID 24504525. S2CID 33537360.

- ^ a b c d e Preparation of Australian Wool Clips, Code of Practice 2010–2012, Australian Wool Exchange (AWEX), 2010

- ^ "Technology in Australia 1788–1988". Australian Science and Technology Inheritance Center. 2001. Archived from the original on 2006-05-14. Retrieved 2006-04-30 .

- ^ Wu Zhao (1987). A bailiwick of wool carbonizing (Ph.D.). University of Unweathered South Cymru. School of Fiber Science and Technology. Archived from the original on 30 October 2022.

- ^ Bradford Industrial Museum 2022. sfn error: atomic number 102 target: CITEREFBradford_Industrial_Museum2015 (help)

- ^ "Merino in Australia". Archived from the original on 2006-11-05. Retrieved 2006-11-10 .

- ^ Avant-garde Nostran, Put on. "Wool Management – Maximizing Woollen Returns". Mid-States Wool growers Cooperative Association. Archived from the original on 2010-01-01. Retrieved 2006-11-10 .

- ^ D'Arcy, John B. (1986). Sheep Management & Wool Technology. NSW University Agitat. ISBN0-86840-106-4.

- ^ 1PP Certification. awex.com.au

- ^ a b c d Robert E. Freer. "The Wool Products Labeling Act of 1939." Archived 2022-06-05 at the Wayback Machine Temple Law Quarterly. 20.1 (July 1946). p. 47. Reprinted at ftc.gov. Retrieved 1 May 2022.

- ^ Ensminger, M. E.; R. O. Parker (1986). Sheep and Goat Science, Fifth Edition. Danville, Illinois: The Interstate Printers and Publishers Inc. ISBN0-8134-2464-X.

- ^ Weaver finch, Litigate (2005). Sheep: small sheep retention for pleasure and net profit. Irvine, CA: Hobby Farm Weight-lift, an embossment of BowTie Press, a division of BowTie Iraqi National Congress. ISBN1-931993-49-1.

- ^ Julia Evelina Smith, Barbara; Kennedy, Gerald; Aseltine, Mark (1997). Beginning Shepherd's Manual, Second Variation. Ames, IA: Iowa State University Press. ISBN0-8138-2799-X.

- ^ "Fiber history". Woolmark. Archived from the original on 2006-08-28.

- ^ a b c d Fernand Braudel, 1982. The Wheels of Commerce, vol 2 of Civilization and Capitalist economy (New-sprung York:Harpist & Row), pp.312–317

- ^ Bell, Hadrian R.; Brooks, Chris; Dryburgh, Apostle of the Gentiles (2007). The English Wool Market, c.1230–1327 . Cambridge: Cambridge Press. ISBN9780521859417.

- ^ "Florentine Woolen Manufacture in the Sixteenth Hundred:Crisis and New Bourgeois Strategies" (PDF). THe Business Story Conference.

- ^ "The remainder of pastoral dominance" Archived 2007-08-19 at the Wayback Machine. Teara.govt.nz (2009-03-03). Retrieved on 2012-08-05.

- ^ 1301.0 – Year Book Australia, 2000 Archived 2022-07-01 at the Wayback Machine, Aboriginal Australian Bureau of Statistics

- ^ "The Account of Fleece" Archived 2022-04-27 at the Wayback Machine. johnhanly.com

- ^ Superwash Wool Archived 2009-03-09 at the Wayback Machine Retrieved on 10 November 2008

- ^ Human race's Finest Basle Record Broken. landmark.com.au, 22 November 2004

- ^ Country Loss leader, NSW Wool Sells for a Quarter of a Million, 7 July 2008

- ^ Exhibitioner accommodate Archived 2011-08-22 at the Wayback Simple machine Retrieved happening 11 November 2008

- ^ "Sheep 101". Archived from the original on 28 November 2022. Retrieved 17 Sept 2022. According to this chart, US output is around 10,000 tonnes (11,000 short tons), hugely discordant with the percentage heel, and way of life outdoors year-to-year variability.

- ^ "WoolFacts" (PDF). Australian Woolen Institution. September 2005. Archived from the original (PDF) connected 2007-11-28.

- ^ Speer, Jordan K. (2006-05-01). "Shearing the Edge of Innovation". Apparel Mag. Archived from the creative connected 2022-05-26.

- ^ Bolt, C (2004-04-07). "AWH to put back up woolen auctions". The Age . Retrieved 2019-05-27 .

- ^ Wool Production in New Zealand. maf.govt.nz

- ^ Wool Marketing. sheepusa.org

- ^ a b c Kadolph, Sara J, ed. (2007). Textiles (10 ed.). Pearson/Apprentice-Mansion. p. 63. ISBN978-0-13-118769-6.

- ^ Østergård, Other (2004). Woven into the Earth: Textiles from Nordic Greenland. Aarhus University Bid. p. 50. ISBN87-7288-935-7.

- ^ Snodgrass, Mary Ellen (2015). World Clothing and Fashion : an Encyclopaedia of History, Culture, and Social Influence. Hoboken: Deems Taylor and Francis. pp. 49–51. ISBN978-1-317-45167-9. OCLC 910448387.

- ^ Rudiment Campestral Radio: Woodhams, Dr. Libby, New research shows cloth underwear helps keep rashes Archived 2011-08-23 at the Wayback Machine Retrieved 2010-3-24

- ^ Blenkin, Max (2011-04-11). "Wool's tough new image". Country Leader.

- ^ "2004/51/1 Trophy and brass, Ermenegildo Zegna Vellus Aureum trophy and plaque, plaster over / chromatic / silver / Au, trophy designed and made by Not Vital for Ermenegildo Zegna, Switzerland, 2001". Powerhouse Museum, Sydney. Archived from the original happening 2007-05-19. Retrieved 2008-04-27 .

- ^ Country Leader, 26 Apr 2010, Finest wool rewarded, Rural Press, Northwestward Richmond

- ^ Australian Wool Network News, Issue #19, July 2008

- ^ "Fletcher Wins Australian Fleece Comp". Walcha Tidings. 24 July 2008. p. 3. Archived from the innovational on 27 July 2008.

External links [edit out]

| | Wikimedia Commons has media related to Wool. |

- . . 1914.

- . New International Encyclopedia. 1905.

can i soak to clean a dense wool area rug

Source: https://en.wikipedia.org/wiki/Wool

Posted by: sebringsittand.blogspot.com

0 Response to "can i soak to clean a dense wool area rug"

Post a Comment